Toyota forklift error codes list. pdf download

Toyota Forklift Error Codes List pdf Download

Toyota Forklift 8FD/FG series Error Codes Download

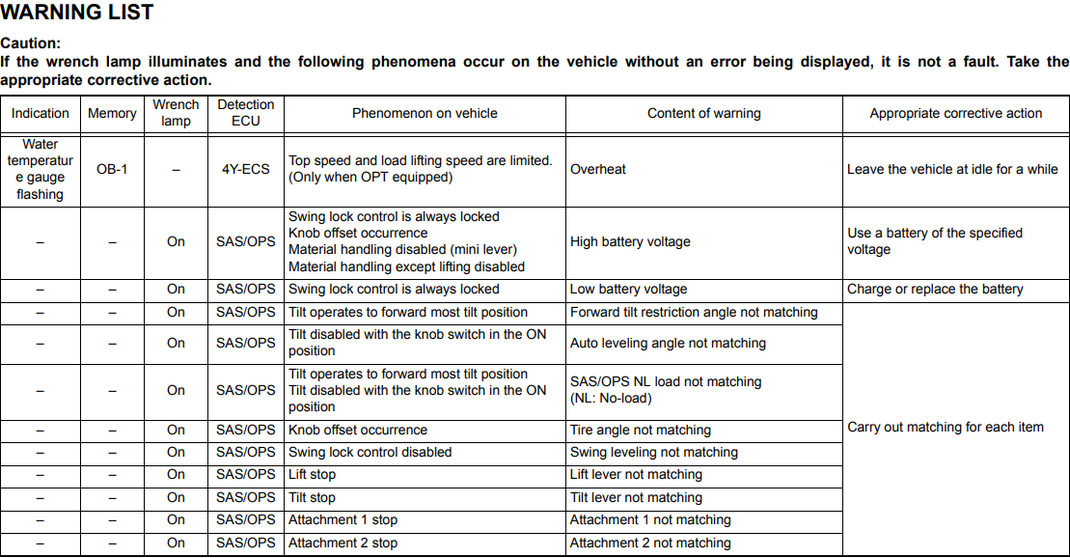

Toyota Forklift fault (error) codes - List Of Diagnosis Codes 1 Download

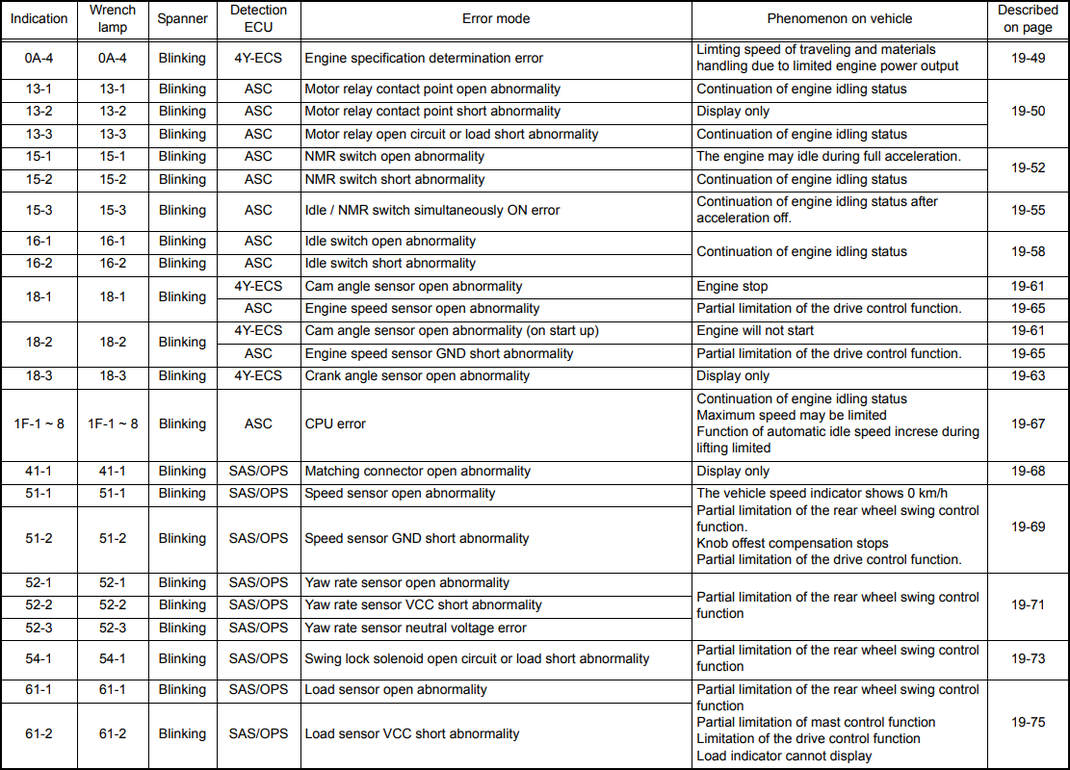

Toyota Forklift fault (error) codes - List Of Diagnosis Codes 2 Download

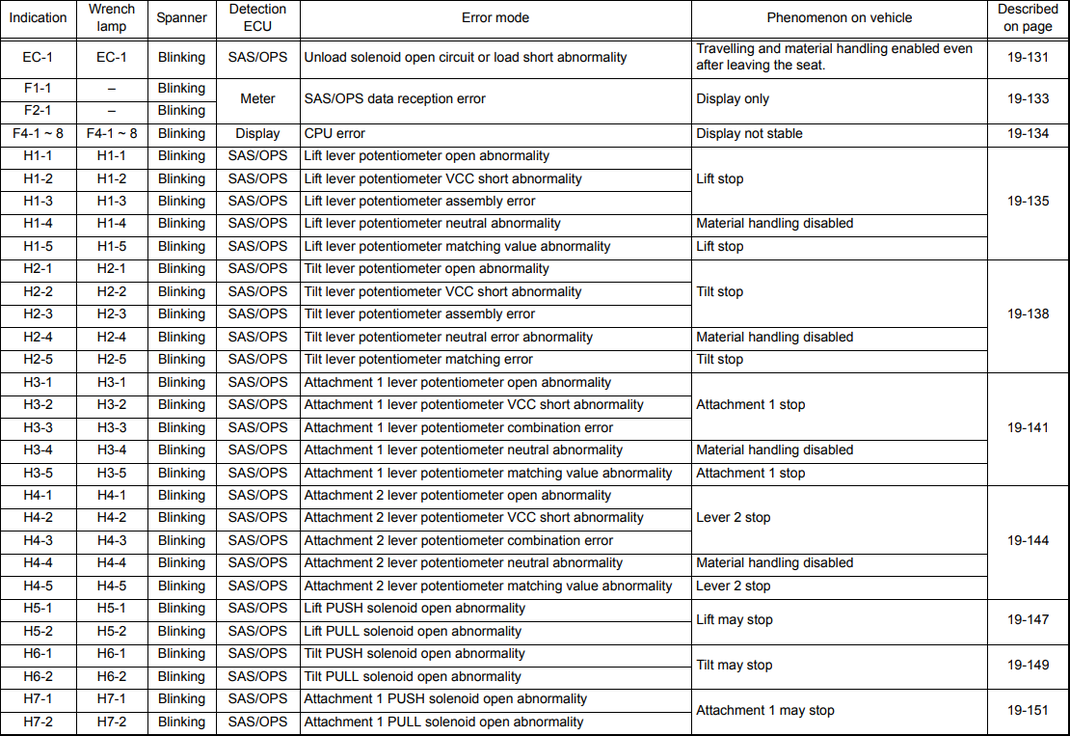

Toyota Forklift fault (error) codes - List Of Diagnosis Codes 3 Download

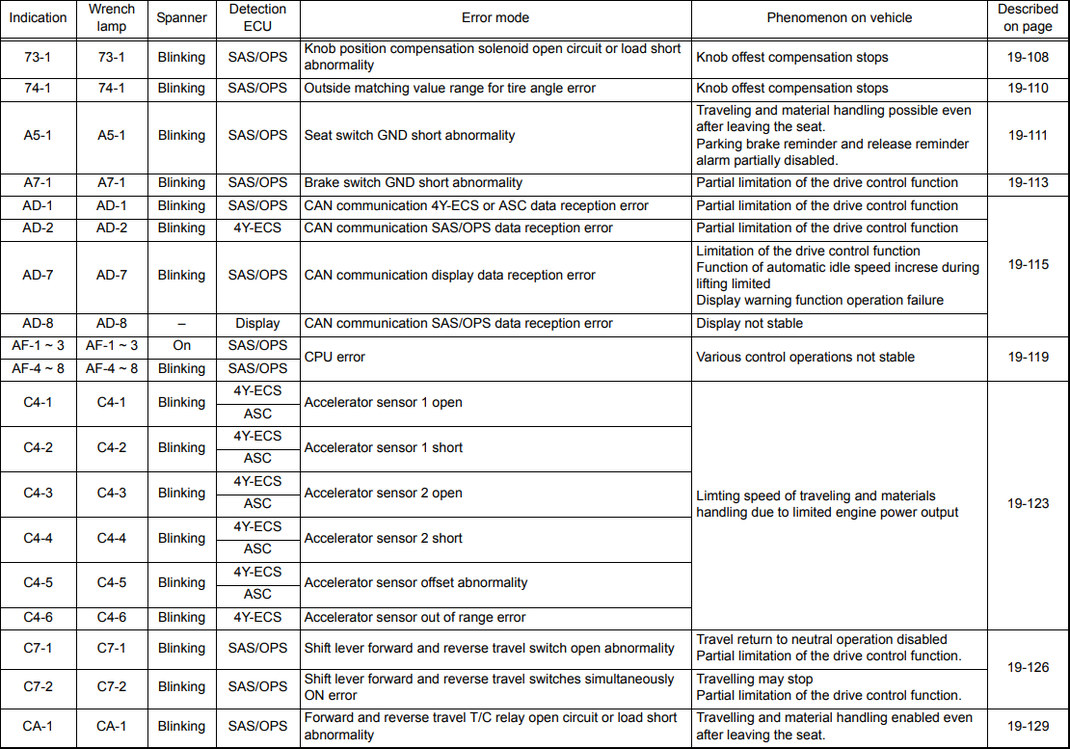

Toyota Forklift fault (error) codes - List Of Diagnosis Codes 4 Download

Toyota Forklift fault (error) codes - List Of Diagnosis Codes 5 Download

Toyota Forklift fault (error) codes - List Of Diagnosis Codes 6 Download

MODEL APPLICATION:

7FBCU15, 7FBCU18, 7FBCU20, 7FBCU25, 7FBCU30, 7FBCU32 7FBCU35, 7FBCU45, 7FBCU55, 7FBCHU18, 7FBCHU25 7FBEU15, 7FBEU18, 7FBEU20, 7FBEHU18, 7FGU15, 7FGU18 7FGU20, 7FGU25, 7FGU30, 7FGU32, 7FDU15, 7FDU18, 7FDU20 7FDU25, 7FDU30, 7FDU32, 8FGU15, 8FGU18, 8FGU20, 8FGU25 8FGU30, 8FGU32, 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30 8FDU32, 7FGCU15, 7FGCU18, 7FGCU20, 7FGCSU20, 7FGCU25 7FGCU30, 7FGCU32, 8FGCU18, 8FGCU20, 8FGCSU20, 8FGCU25 8FGCU30, 8FGCU32, 7FGU35, 7FDU35, 7FGKU40, 7FDKU40 7FGU45, 7FDU45, 7FGAU50, 7FDAU50, 7FGU60, 7FDU60, 7FGU70 7FDU70, 7FGU80, 7FDU80, 7FGCU35, 7FGCU45, 7FGCU55 7FGCU60, 7FGCU70

GENERAL INFORMATION:

All three error codes are for the same condition. • A5 is for sit-down electric trucks (Class I) • A5-1 is for 8-Series internal combustion trucks (Class IV & V) • 1-1 is for 7-Series internal combustion trucks (Class IV & V) with OPSS (Operator Presence Sensing System)

Further information concerning these codes can be found in the following manuals:

7FBCU15-55 ►OPSS Manual CU335 page 3-9 7FBEU15-20 ►OPSS Manual CU341 page 1-10 7FGCU15, 18, S20 ►OPSS Manual CU042 page 1-19 7FGU15-32, 7FDU15-32, 7FGCU20-32 ►OPSS Manual CU040 page 1-18 7FGU35-80, 7FDU35-80, 7FGCU35-70 ►OPSS Manual CU041 page 1-17 8FGCU15, 18, S20 ►Service manual 00700-X8880-71 page 19.1-82 8FGU15-32, 8FDU15-32, 8FGCU20-32 ►Service manual 00700-X8880-71 page 19-111

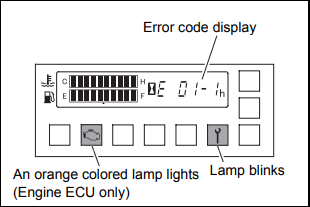

DIAGNOSIS DISPLAY METHOD

1. Diagnosis display method The diagnosis is displayed by means of an error code as shown in the illustration to the left, and by the lights turning on. When the ignition key switch is turned ON, the lamp lights once to allow checking for the bulb, and then turns off again if the status is normal. With the ignition key switch ON, if an abnormality is detected when the vehicle is stopped, travelling or performing meterials handling operations, an error code is displayed and the lamps turn on as a warning. When this happens, stop the vehicle immediately and check the error code.

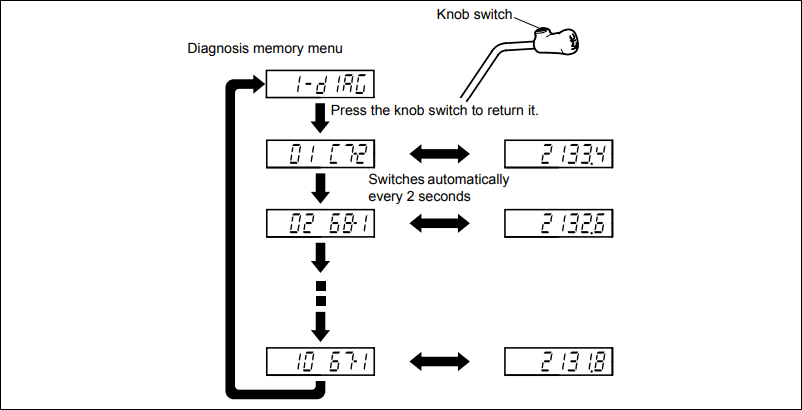

2. Diagnosis memory display method To display the diagnosis memory display, there are a method using the hour meter and tilt lever, a method using the optional display, and a method using a plug-in analyzer. Here the display method using the hour meter and tilt lever is described. (1) From the main menu, display the diagnosis memory menu. For how to display the main menu, refer to page 18-30. (2) A diagnosis No. and error code are displayed each time the knob switch is pressed and released. Each error code and the time at which it occurred are displayed alternately at 2 second intervals.

(3) Connect the matching connector and turn the ignition key switch OFF.

LIST OF DIAGNOSIS CODES

Translated from Indonesian!

Original text error codes Download

41-1 Matching connector abnormal Only the Connector display is faulty

Matching cable is broken

Controller is broken

51-1 Speed sensor abnormal Speed indicator keeps showing 0 km/h Connector is faulty

51-2 Rear wheel swing control Damaged connector cable

Steer knob is not in position Speed sensor is broken

Controller is broken

52-1 Yaw rate sensor abnormal Rear wheel swing control is limited. Broken connector

52-2 Connector cable is damaged

52-3 Yaw rate sensor is faulty

Controller is broken

54-1 Swing lock solenoid abnormal Rear wheel swing control is limited. Broken connector

Broken connector cable

Swing lock solenoid is broken

Controller is broken

61-1 Load sensor abnormal Rear wheel swing control is limited. Broken connector

61-2 Control mast function is partially restricted Connector cable is damaged

Drive control function is limited (MFD opt) Load sensor is faulty

Load indicator does not appear on the display (MFD) The controller is broken

Error mode Symptoms on forklift Possible causes

damaged

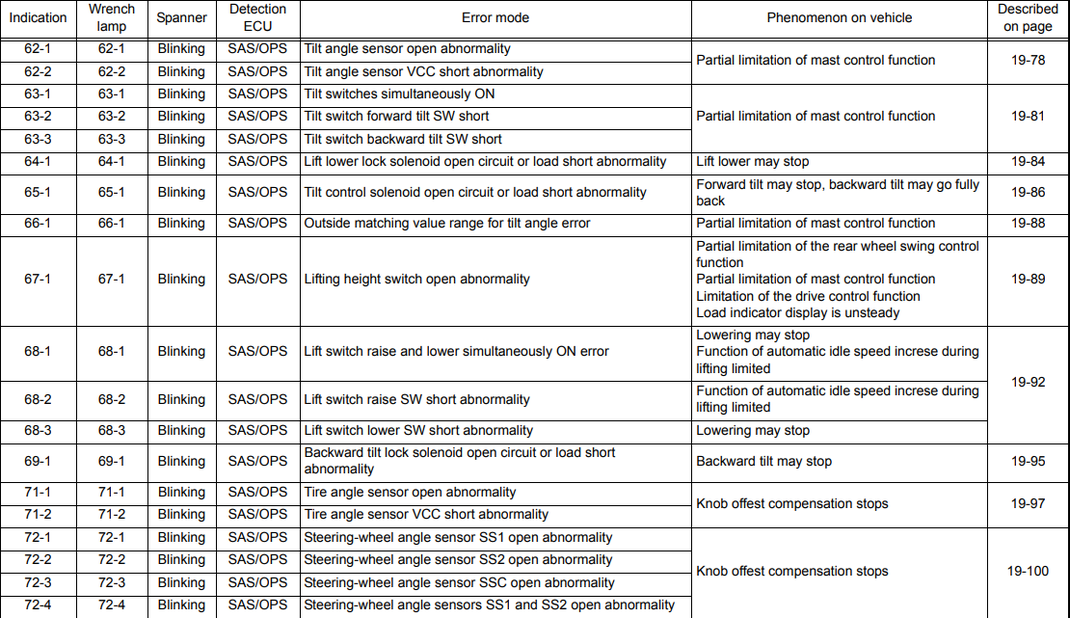

62-1 Tilt angle sensor abnormal Mast control function is partially restricted Connector is faulty

62-2 Connector cable is damaged

Broken tilt angle sensor

Controller is broken

63-1 Tilt lever switch abnormal Mast control function is partially restricted Connector is faulty

63-2 Forward tilt switch is broken

63-3 Backward tilt switch is broken

Broken cable

Faulty switch installation

Controller is broken

64-1 Lift lock solenoid abnormal Fork won't come down Connector is broken

Broken connector cable

Broken lift lock solenoid

Controller is broken

65-1 Tilt control solenoid abnormal Forward tilt cannot operate, but Connector is damaged

backward tilt operable. Broken connector cable

Broken tilt control solenoid

Controller is broken

66-1 Abnormal matching measurement value The control mast function is partially restricted. The horizontal tilt angle value does not match.

Tilt forward angle value

it is not in accordance with.

Measuring value of load sensor

it is not in accordance with.

67-1 Lifting height switch abnormal Partial rearwheel swing control function Faulty connector

restricted. Broken connector cable

Mast control function is partially restricted Lifting height swt is broken

Drive control function is restricted Controller is faulty

Load indicator display changes IG fuse blown

68-1 Lift switch abnormal Fork won't come down Connector is broken

68-2 Raising lift swt is broken

68-3 Lowering lift swt is broken

Broken connector cable

The swt elevator installation is broken

Controller is broken

Error mode Symptoms on the forklift Possible cause of failure

69-1 Backward tilt lock solenoid Backward tilt does not operate Connector is faulty

abnormal Connector cable is damaged

Backward tilt lock solenoid is faulty.

Controller is broken

71-1 Tire angle sensor abnormal Steer knob is not in position Connector is faulty

71-2 Connector cable is damaged

Broken sensor

tire angle sensor joint,

rear axle link syst. damaged

Controller is broken

72-1 Steering angle sensor abnormal Steer knob is not in position Connector is faulty

72-2 Connector cable is damaged

72-3 Sensor is faulty

72-4 Controller is faulty

73-1 Abnormal solenoid knob position Steer knob out of position Connector is faulty

Broken connector cable

Broken solenoid

Controller is broken

74-1 Measuring value of matching tire angle Steer knob is not in position Matching value

wheel alignment error no in accordance

A5-1 Seat switch abnormal Drive & hydraulic system can operate Connector is faulty

even if the operator is not sitting in the operating chair The connector cable is damaged

Broken switch

Controller is broken

A7-1 Abnormal brake switch Function of partially restricted drive control Connector is faulty

Broken brake switch

Broken connector cable

Controller is broken

AF-1

AF-2

AF-3

AF-4

AF-5

AF-6

AF-7

AF-8 CPU abnormal All control functions are unstable Controller is faulty

C7-1 Shift lever switch abnormal Cannot be positioned to neutral Connector is faulty

C7-2 Drive control function is partially restricted Forward switch is faulty

Reverse switch is broken

Broken cable

Faulty switch installation

Controller is broken

CA-1 Forward-reverse travel Torque Drive system and hydraulic system can Connector damaged

converter relay abnormal is operated even when operator is not seated Forward travel cable

the relay operator seat is broken

Forward travel relay

damaged

reverse travel cable

broken relay

Reverse travel relay

damaged

Controller is broken

EC-1 Unload solenoid abnormal Drive system and hydraulic system can Connector is faulty

operated even if the operator is not seated Connector cable is damaged

in operator seat Unload solenoid is broken

Controller is broken

F1-1 Combination meter abnormal Problem on the display Connector is damaged

F1-2 Hour meter cable is damaged

Hour meter is broken

Controller is broken

F4-1~8 CPU error CPU abnormal Multi-function board

broken display

H1-1 Lift lever potentiometer abnormal Lift cannot operate Connectro is faulty

H1-2 The potentiometer wire is damaged

H1-3 Potentiometer is broken

H1-4 Controller is broken

H1-5 Fuse blown

H2-1 Tilt lever potentiometer abnormal Tilt does not operate Connectro is faulty

H2-2 The potentiometer wire is damaged

H2-3 Potentiometer is broken

H2-4 Controller is broken

H2-5 Fuse blown

H3-1 Attachment 1 lever potentiometer Attachment 1 does not operate Connectro is faulty

H3-2 abnormal Potentiometer cable is damaged

H3-3 The potentiometer is faulty

H3-4 Controller is broken

H3-5 Fuse blown

H4-1 Attachment 2 lever potentiometer Attachment 2 does not operate Connectro is damaged

H4-2 abnormal Potentiometer cable is damaged

H4-3 The potentiometer is faulty

H4-4 Controller is broken

H4-5 Fuse blown

H5-1 Lift solenoid abnormal Elevator may not operate Faulty connector

H5-2 Elevator cable (PUSH) is damaged

Solenoid lift (PUSH) is broken

Elevator cable (PULL) is broken

Solenoid lift (PULL) is broken

Controller is broken

H6-1 Solenoid Tilt Abnormal Tilt may not operate Connector is faulty

H6-2 Faulty tilt (PUSH) cable

Solenoid tilt (PUSH) faulty

Broken tilt (PULL) cable

Solenoid tilt (PULL) faulty

Controller is broken

H7-1 Attachment 1 abnormal solenoid Attachment 1 may not work Connector is damaged

H7-2 operating Att 1 (PUSH) cable is faulty

Solenoid Att 1 (PUSH) is faulty

Att 1 (PULL) cable is damaged

Solenoid Att 1 (PULL) is faulty

Controller is broken

H8-1 Attachment 2 abnormal solenoid Attachment 2 may not work Connector is damaged

H8-2 operating Att 2 (PUSH) cable is faulty

Solenoid Att 2 (PUSH) is faulty

Att 2 (PULL) cable is damaged

Solenoid Att 2 (PULL) is faulty

Controller is broken

HA-1 3/4-way change relay abnormal Attachment transfer is not possible Connector is damaged

operating Relay cable 1 is damaged

Relay 1 is broken

Relay cable 2 is damaged

Relay 2 is broken

Controller is broken

Error mode Symptoms on forklift Possible causes

broken WARNING LIST

IF THE WRENCH LAMP IS ON AND WITH THESE SYMPTOMS BELOW ON

Hadi (Monday, 12 August 2024 08:01)

I have an error in my forklift

8fgj30

Error:ed-1

How can i repair this?

adj (Monday, 26 February 2024 10:57)

03:103 error

Justin (Friday, 26 January 2024 18:15)

E225?

Manuel gomez (Friday, 26 January 2024 00:17)

Montacargas reach, 9BRU23, QUIERO SABER LA FALLA POR EL CUAL SE BLOQUEA

Armando Ramirez (Thursday, 10 August 2023 00:49)

After repairs how clear codes?

Greg Wilder (Friday, 21 July 2023 06:41)

I have a Raymond/Toyota 520 OPC30TT stock picker with error code 41 and then 31 appearing, it has no drive or power steering. it does still lift.

Would anyone have any ideas.

Heather B (Sunday, 16 July 2023 03:23)

I have a blinking wrench and a code E 12-4 coming up 2016 Toyota forklift 61324-serial 8FDU20 model

Any ideas?

jim (Thursday, 13 July 2023 14:45)

Toyota 7FBCU25

has a code 57-1;64-1

Change line contactor and maybe I have wires in the wrong palace?

Can you supply me with a wiring diagram of this area?

One more thing the codes where up before I replace the line contactor and after replacing the contactor No display at all help!

Andres (Saturday, 17 June 2023 18:13)

Tengo ya varios dias con el código de error 61-1no ce como eliminar si me pudieran ayudar muchas gracias montacargas Toyota modelo 7FBCU18

Atanu Parida (Friday, 02 June 2023 08:21)

Please send me toyota forklift error code list

Model no.8fbe20

Error code.CO.2

F5-1, F5-4

Atanu Parida (Friday, 02 June 2023 08:06)

I need error code.F5-1, F5-4, Co-2

Titus top (Tuesday, 02 May 2023 19:34)

My forklift 8fg25 forks can't go down and can't tilt forward and backward.

Amr taha (Sunday, 30 April 2023 08:52)

Hello,

on a Toyota forklift 8pBCU25, what does the erroneous codes

CB-2&AD-1&AD-2 means

Ramesh (Sunday, 02 April 2023 19:27)

54-3 error in Toyota 3 ton forklift

Gela Geldiashvili (Saturday, 27 August 2022 08:07)

Hello,

on a Toyota forklift, what does the erroneous code CB-1 mean?

Юрий (Saturday, 06 August 2022 16:41)

Погрузчик Тойота 7FGU30 ошибок нет, но при полной нагрузке в движении теряет мощность? Какие могут быть вероятные причины неисправности? С уважением Юрий Александрович.

Duy Lương Trần (Friday, 29 July 2022 11:48)

Error A0-5 on Toyota 7FB20 electric forklift, manufactured in 2006. Thank you very much!

владимир (Monday, 21 March 2022 05:06)

ERROR 107 вилочный погрузчик HANGCNA

Kasco (Wednesday, 09 March 2022 12:10)

Error code C5-5 not moving

si (Monday, 02 August 2021 18:42)

code E0-1?

Omar orduno (Sunday, 13 June 2021 22:45)

montacargas eléctrico Toyota modelo 7fcu15 presenta error c3-1

nam (Friday, 11 June 2021 11:18)

toyota 7fbrs 15 error code f5-1 , f5-4

Ravindu Bandara (Tuesday, 08 June 2021 08:15)

What is the meaning of E 59-1 error code in GENEO 35

zoltan (Tuesday, 16 March 2021 09:41)

1C-2 code 52-8FDF25 (1ZS engine)

Anybody knows this code?

de Vries (Wednesday, 24 February 2021 19:51)

Mijn toyota traico heeft foutcode 73 wat houdt dat in?

Joel (Friday, 13 November 2020 23:05)

Just serviced 7 series 7fbcu30 and need to reset the maintenance timer

Joel (Friday, 13 November 2020 23:02)

How to reset maintenance hours reminder

Armando garrido (Wednesday, 23 September 2020 21:14)

Hi need manual for forklift

How much cost me grgarryciencia@aol.com

For Toyota 8 series and any lift to also any scanner or software

Thanks

Ole (Monday, 21 September 2020 08:30)

does anyone know the error code "joy M not connected"

Robert Sieow (Tuesday, 28 July 2020 16:22)

pls send

Gustavo D (Tuesday, 14 April 2020 16:01)

I have a Toyota diesel forklift model 8FDU20 a code came up on the display (E AD 1) the machine won't start. I checked many different connectors and sensors but nothing seemed wrong.

I need some fresh ideas from someone smart, please help!

Jose (Thursday, 30 January 2020 21:49)

Tengo un equipo Toyota 8fdu30 serie 60532 me da código 11-5 y deja de caminar hacia el frente

manish chauhan (Wednesday, 29 January 2020 17:27)

it is most usebal document

JIM K (Monday, 27 January 2020 13:07)

Working on a Hyster ROES30 order picker which has a code A5 31 on display board in the lower part of the compartment, NEED HELP

Josh Gering (Tuesday, 21 January 2020 23:26)

Code 72-4 Steering angle sensor.

Lift does not have said sensor. How do I remove/disable this parameter? Everything working fine, but lift won't quit alarming. Customer getting irritated.

kwan (Tuesday, 05 November 2019 15:59)

CODE E01-1是什么意思呢

Rick (Wednesday, 07 August 2019 21:33)

I have a toyota Electric Fork lift That has had some serious problems as I had to get into it pretty deep to find out why when the owners guys turned on the key nothing powered up? Im not a class A electric fork lift technician but I know enough about electrical that I chased down a Five pin plug that was all melted together and shorted out I removed burnt socket and replaced the burnt wires and got power back to the ignition and truck I got it so it powers the hoist and power steering but have do final drive forward or reverse I have a wrench and a Code A 8 I did see another electrical socket that looked burnt pretty badly I didnt play with it but I'm thinking I'm probably going to have to cut that socket out and clean wires back and reconnect them together to get the drive motor to start so the fork truck can move back and forth! I'm trying to find out what the A 8 code is and the proper way to reset the computer to remove the wrench symbol and clear all codes. Thank you for your time, Rickey

Kevin Stahl (Wednesday, 29 May 2019 19:18)

Please could you email me the code sheet of a Toyota electric forklift Model number 5FBE15

Pepo (Wednesday, 15 May 2019 22:07)

I've been fighting with this code h5-1

Robert Shamonski (Monday, 22 April 2019 20:45)

EA5-1 trying to identify code

Jose Sanchez (Monday, 15 April 2019 17:58)

I have a forklift 3 wheel sit down model number 7FBEU15 and a code pops up that is AD6 and AD5 if you can help me what those code mean I’ll appreciate it

Sammy G. Polinar (Thursday, 04 April 2019 09:13)

Please provide me the Electrical Diagram of Toyota Electric Fork Lift Model: 7FBE20.

My Fork Lift is stop due to Electrical Problem