Caterpillar Engine, Service Manual, Wiring Diagrams (Error Codes)

Caterpillar Servicing Engine PDF Free Download

2WBl-Up (Engine)

2RD1-Up (Engine)

2TD1-Up (Engine)

1ZF1-Up (Engine)

3YF1-Up (Engine)

4XF1-Up (Engine)

4RG1-Up (Engine)

5SJ1-Up (Engine)

2BM1-Up (Engine)

3DM1-Up (Engine)

4GM1-Up (Engine)

5XM1 -Up (Engine)

6PM1-Up (Engine)

7HM1-Up (Engine)

7KMl-Up (Engine)

7SM1-Up (Engine)

8EM1-Up (Engine)

8RM1-Up (Engine)

4TN1-Up (Engine)

6HN1-Up (Engine)

6PN1-Up (Engine)

6WN1-Up (Engine)

7RN1-Up (Engine)

8CN1-Up (Engine)

8KN1-Up (Engine)

9AN1-Up (Engine)

9NN1-Up (Engine)

4ZR1-Up (Engine)

1LS1-Up (Engine)

3LS1 -Up (Engine)

3MS1-Up (Engine)

3NS1-Up (Engine)

3PS1 -Up (Engine)

3RS1 -Up (Engine)

3SS1-Up (Engine)

3TS1-Up (Engine)

3WS1-Up (Engine)

3XS1-Up (Engine)

5PS1-Up (Engine)

8FS1-Up (Engine)

1 NWI-Up (Engine)

1PW1-Up (Engine)

1TW1-Up (Engine)

2FW1-Up (Engine)

2GWl-Up (Engine)

2HW1-Up (Engine)

2JW1-Up (Engine)

3CW1-Up (Engine)

3DW1-Up (Engine)

32W1-Up (Engine)

4AW1-Up (Engine)

4BW1-Up (Engine)

5AW1-Up (Engine)

2321-Up (Engine)

2421-Up (Engine)

2521-Up (Engine)

2EZ1-Up (Engine)

6721-Up (Engine)

6HZ1-Up (Engine)

7021 -Up (Engine)

73Z1-Up (Engine)

7821-Up (Engine)

8121-Up (Engine)

9B21-Up (Engine)

Caterpillar Customer Communication Module (CCM) Diesel Engines Operation And Maintenance Manual Download

3064 and 3066 Engines for Caterpillar sy Built Machines Specifications 6LK1-Up (Engine) 7JK1-Up (Engine) Download

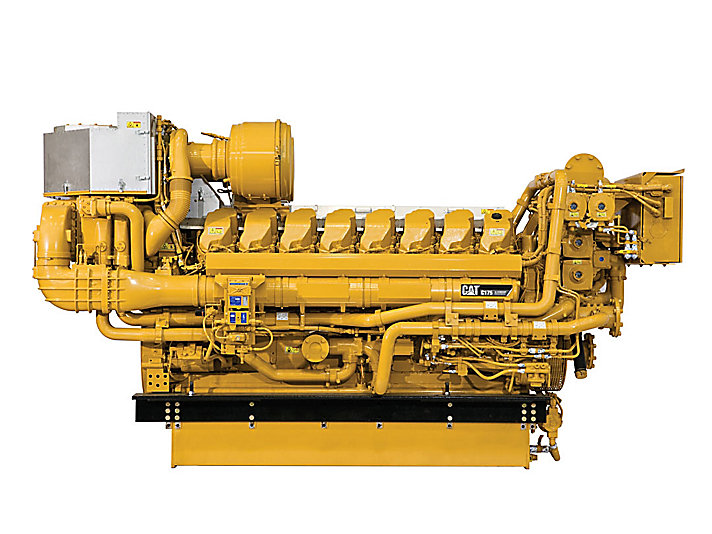

Caterpillar - Troubleshooting For C175-16 & C175-20 Engines For Caterpillar Built Machines Download

Troubleshooting C27 and C32 Generator Set Engines Download

DWB1-Up (Generator Set)

SXC1-Up (Generator Set)

MED1-Up (Power Module)

MEG1-Up (Power Module)

WDR1-Up (Generator Set)

Caterpillar C15 ACERT Dissasembly and Assembly Download

Fuel Priming Pump - Remove and Install

Caterpillar 2006 Troubleshooting C11, C13, C15 and C18 Industrial Engines Download

JRE1-Up (Engine)

WJH1-Up (Engine)

LGK1-Up (Engine)

GLS1-Up (Engine)

Caterpillar 2005 Troubleshooting 11, C13, C15 and C18 Industrial Engines Download

JRE1-Up (Engine)

WJH1-Up (Engine)

LGK1-Up (Engine)

GLS1-Up (Engine)

CAT Engine TOOL OPERATING MANUAL SMCS Code 0782

9U-5132 Timing and Fuel System Setting Tool Group Download

Troubleshooting 3516B and 3516B High Displacement Engines for Caterpillar Built Machines Download

FDB1-Up (Machine)

8WM1-Up (Engine)

7TR1-Up (Engine)

Diesel Engine and Fuel System Repair Download

Caterpillar 3208 Diesel Truck Engine Service Manual Download

Diagnostic Tools New Tools 1st Supplement 3rd Supplement 4th Supplement Download

Cat 3406 Engine Parts Manual Download

Cat C15 Engine Parts Manual Download

Caterpillar 3116 Instructions Manual Download

Caterpillar 3208 User Manual Download

Caterpillar 3406E Maintenance Manual Download

Caterpillar 3500B Application And Installation Manual Download

Caterpillar 3500B Series II Operation And Maintenance Manual Download

Caterpillar 3508 Specifications Download

Caterpillar 3412E Operation & Maintenance Manual Download

Caterpillar 3512 Maintenance Intervals Manual Download

Caterpillar 3512B Operation And Maintenance Manual Download

Caterpillar 3512C Operation And Maintenance Servicing Engine Manual Download

Cat 3600 Series and C280 Series Diesel Engine Fluids Recommendation Download

Cat 72H PIPELAYER Operation and Maintanence Manual Download

Caterpillar 3126B/326E Systems Operation Testing And Adjusting Download

Caterpillar except 3600 Operation And Maintenance Manual Download

Caterpillar COMMISSIONING – 3600/C280 Application And Installation Manual Download

Caterpillar 3126B Operation & Maintenance Manual Download

Tool List 3500 Caterpillar Download

Truck Engine

BKD1-Up (Engine)

G3E1-Up (Engine)

DPF1-Up (Engine)

1AJ1-Up (Engine)

8YL1-Up (Engine)

CKM1-Up (Engine)

CRP1-Up (Engine)

7AS1-Up (Engine)

8SZ1-Up (Engine)

9SZ1-Up (Engine)

Caterpillar Marine Engine Application And Installation Manual Download

Caterpillar PKA1-Up Operation And Maintenance Manual Download

Caterpillar SEHS9031 Installation Manual Download

Operation and Maintenance Manual - 3600 Distillate Fuel Engines SENR6965

Operation and Maintenance Manual - 3600 Heavy Fuel Engines SENR6966

Operation and Maintenance Manual - 3612/3616 Fast Vessel SENR7083

Systems Operation - 3606 and 3608 Engines SENR3599

Systems Operation - 3612 and 3616 Engines SENR3593

Maintenance Manual - Schedules for Equipment Maintenance SEBU6103

Maintenance Management Recommendations - 3600 Distillate Fuel Engines SELU6965

Maintenance Management Recommendations - 3600 Heavy Fuel Engines SELU6966

Operation with Damaged Turbocharger Service SEHS8704

Specifications - 3606 and 3608 Major Components SENR3598

Specifications - 3612 and 3616 Major Components SENR3592

Disassembly and Assembly - 3606 and 3608 Engines SENR3600

Disassembly and Assembly - 3612 and 3616 Engines SENR3594

Service Manual - 3606 and 3608 Engines SENR3595

Service Manual - 3612 and 3616 Engines SENR3590

Special Edition Engine News - Serviceability SEBD9129

Parts - 3600 Parts SEBP3600

Parts - 3600 Parts (Microfiche) SBFY0628

Service Manual - 3161 Governor SENR3028

Service Manual - 2301 Electric Governor SENR3585

Service Manual - Heinzmann Governor-Generator Sets SENR4622

Service Manual - Heinzmann Governor-Marine SENR4661

Caterpillar Front End Loaders manuals

Caterpillar engine wiring diagrams

C15 Cat Engine Wiring Schematics Download

Cat 3126 EWD Download

Caterpillar 3176B and 3406E Wiring Download

Caterpillar 3176b, c-10, c-12. 3406e Electrical system Download

Caterpillar C10 -C12, 3176B, 3406E Engine Wiring Diagram -Schematic, Laminated Download

Engine Wiring, Caterpillar Download

T-630 CAT Engine Wiring Download

List of Fault Identification Codes (FMI)

FMI code Type of fault type

0 Data are reliable, but exceed the normal operating range of the parameter change

1 The data are reliable, but below the normal operating range of the parameter change

2 Data is erratic, intermittent or incorrect

3 Voltage above normal or short circuit to a higher voltage circuit

4 Voltage below normal or short circuit to a lower voltage circuit

5 Current is below normal or circuit is open

6 The current is above normal or the circuit is closed to ground

7 Inadequate reaction of the mechanical system

8 Anomalous frequency, pulse width or period of a signal

9 Abnormal data exchange

10 Anomalous rate of change

11 Fault type not defined

12 Faulty device or component

13 Parameter outside calibration

FMI 00 - The data is reliable, but it exceeds the normal operating range of the parameter change

For each electronic control system, the upper limit of the expected operating range of the signal value change is set. The upper limit is set based on the expected maximum value of the parameters (for example, the temperature of the torque converter). A sensor that continues to function but generates a signal whose value is higher than the expected upper limit will cause the FMI 00 code to be registered.

Example - The normal factor of the sensor signal with pulse-width modulation (the value proportional to the width of pulses) should not exceed 80%. If the sensor generates a signal with a duty ratio of 81%, it means that it continues to function, but the signal value exceeds the set upper limit of its range.

FMI 01 - The data is reliable, but below the normal operating range of the parameter change

For each electronic control system, the lower limit of the expected operating range of the signal value change is set. The lower limit is set based on the expected minimum value of the parameters (eg oil pressure in the engine). A sensor that continues to function but generates a signal whose value is below the expected lower limit will cause the FMI 01 code to be registered.

Example - The minimum duty cycle of most sensors with pulse width modulation is at least 5%. If the sensor generates a signal with a duty cycle of 3%, it means that it continues to function, but the signal value is below the set lower limit of its range.

FMI 02 - Data is erratic, intermittent or incorrect

The appearance of the FMI 02 code occurs when there is a signal from the corresponding component. Then, the information signal data can change as follows.

• The data disappears.

• Data becomes unstable.

• The data becomes incorrect.

The values of the data at certain intervals can be correct, but not in others. The appearance of this code can also be associated with the incorrect exchange of information between electronic units. For example, in the case where the VIMS system requests engine speed data from the engine control unit via a data link from Caterpillar.

FMI 03 - Voltage above normal or short circuit to a higher voltage circuit

The code FMI 03 appears in cases where the values of voltages measured in a particular system or element become high. The reason for the appearance of the FMI 03 code is often associated with signal circuits.

The reason for the appearance of the FMI 03 code can be the following elements of the system.

• Sensor

• Harness wiring harness

• Suitable electronic control units

The possible reasons for the appearance of the FMI 03 code may be the following.

• The sensor generates an AC signal (per operating cycle), and the signal hangs at the maximum value.

• The signal wire in the harness is shorted to the power supply circuit of the sensor or to a circuit under voltage that exceeds the voltage of the power supply.

• A break in the signal wire between the sensor and the electronic control unit. On the input circuits of electronic controls and controls, a positive voltage is normally maintained. For example, if the sensor is disconnected, the voltage in the input circuit of the control unit will be 5 VDC.

• In the electronic control unit, there is an internal short circuit of the sensor signal circuit contact in the connector with the positive power supply circuit. In addition, the faulty electronic control unit may not correctly sense the normally functioning signal circuit of the sensor.

FMI 04 - Voltage below normal or short circuit to a lower voltage circuit

The FMI code 04 is similar to the FMI code 03. However, the FMI code 04 indicates that the voltage values are below acceptable values. The appearance of the FMI 04 code is most often associated with a malfunction of the signal circuits. The FMI code 04 is similar to the FMI 06 code and is sometimes used instead.

The reason for the appearance of the FMI 04 code can be the following elements of the system.

• Sensor

• Harness wiring harness

• Suitable electronic control units

The following reasons may be the possible reason for the appearance of the FMI 04 code.

• Sensor signal hangs at a low level or level close to the mass potential.

• The signal wire in the harness is shorted to ground.

• There is a short in the electronic control unit of the signal contact of the connector to ground.

FMI 05 - Current is too low or the circuit is open

The FMI code 05 appears in cases where the electronic control unit determines that the current values are low.

The most likely cause of the appearance of the FMI 05 code is a chain break or bad contact in the harness connectors.

FMI 06 - Current is above normal or the circuit is closed to ground

The FMI code 06 is similar to the FMI code 05. However, the FMI code 06 indicates that the current values are higher than the permissible values. The appearance of the FMI 06 code is most often associated with a malfunction of the output circuits in the electronic control units.

Example - FMI code 06 appears when the circuit is shorted to ground.

The reasons for the appearance of the codes FMI 06 and FMI 04 are very similar, and the FMI 06 code is sometimes used instead of the FMI code 04.

FMI 07 - Inadequate response of the mechanical system

The FMI code 07 appears when the electronic control unit sends an electrical command to the mechanical system, and the result does not fit within the specified range of values.

Example - FMI code 07 appears when the gearbox is slowly shifted by the command of the electronic control unit (EPTC II) due to the slow operation of the solenoid.

FMI 08 - Anomalous frequency, pulse width or period

The FMI code 08 appears when the frequency or width of the signal pulse is outside the specified range.

Note: Period is the time in seconds for one cycle of signal change at a certain frequency. The period is defined as the reciprocal of the frequency in Hz (1 / frequency, Hz).

FMI 09 - Abnormal data exchange

The appearance of the FMI 09 code depends on the serviceability of the communication link between the electronic means on the data channel. The FMI 09 code occurs if the electronic unit is unable to receive information from another electronic unit and is waiting for information to be received.

FMI 10 - Abnormal Rate of Change

The appearance of the FMI code 10 is associated with more or less than the expected rate of change in the signal.

Example - This code is generated if the signal from the output shaft speed sensor on the dump truck indicates that the dump truck is accelerating faster than it can be when it is used in real conditions.

FMI 11 - Fault type not defined

The FMI code 11 appears when the electronic unit registers more than one FMI code for one fault.

FMI 12 - Faulty device or component

The FMI code 12 indicates the following status: the electronic control unit sends a signal to another electronic unit via a data link. The electronic unit is waiting for a response, but either does not receive any response, or receives an incorrect response.

The FMI code 12 can also indicate the following status:

The electronic unit is expected to periodically send data, but does not send.

The appearance of the FMI code 12 can also be associated with a data link failure.

FMI 13 - Parameter outside calibration

With this state of the mechanical part, the parameters of the electrical signal go beyond the limits set by the electronic control unit.

Diesel Engines Caterpillar

The famous American company Caterpillar is the world's leading manufacturer of diesel engines for marine, railroad and heavy-duty transport, construction and agricultural equipment, as well as equipment of various classes and purposes, including power plants of the highest quality and reliability.

The Cat engines used in diesel power plants are engineered to provide long, trouble-free operation in all climates of the planet. That is why these solutions are the most relevant, some regions of which are characterized by extremely high summer and critically low winter temperatures.

The materials used in the production of power plants for diesel power plants and the latest technologies ensure the highest environmental friendliness and low fuel consumption. And the famous German quality, reliability and durability are reflected in tens of thousands of copies of engines produced annually, which are not only installed at the company's own power plants, but are also the main power generating equipment of many leading world brands.