John Deere Diagnostic Fault Codes

Fault codes combine 9560, 9660 John Deere

Troubleshooting

To save time and money, follow these seven rules for quick and accurate troubleshooting:

1. EXPLORE A NODE

In other words, do everything that depends on you. Study the operating instructions for the driver-mechanic, as well as this guide to know how the individual nodes work and how they function in the operating system.

Check the latest service information. Read it and keep it readily available. This data may contain information about the cause of the problem that you encountered and how to troubleshoot it.

2. TAKE A LOOK WITH A BODY

Ask the driver, as the vehicle drove, when the strip was marked.

Find out that it was not as usual in the work of the combine.

Also, find out whether any work has been done on the machine yourself. You may have found a problem with someone else, but you should be aware of the measures that have already been taken.

Find out how the combo was operated, and how often the maintenance was carried out.

A large number of malfunctions arise as a result of good yields and careless handling.

3. GET COMBINE IN WORK

If the combine can be operated, try to drive it by yourself. Do not rely on the word of the driver-mechanic, check everything.

Do the given data show the measuring instruments? If not, it is possible that the unit provided by the device is not very functional, or the measuring device is incorrect.

How does the Combine drive? Does it function too fast, too slowly, incorrectly, or does it not function in general?

Do you feel the pedal resistance? Do they fall asleep?

Is there a hangover or smoke?

Are there any unusual noises? If yes, then?

4. OCMOTPITE COMBINE

Get out of the cab and take a look at the combine.

Look, listen, understand - everything can help you in the error message.

Take a good look at all parts and assemblies.

Check the absence of welding defects, flat fixed parts, damaged

connections, worn or torn wires, etc.

Note down all faults while viewing.

5. COCTABLE LIST OF FUNCTIONAL PRODUCTS

On the basis of the data obtained during the execution of pp. 1 - 4, list the possible reasons for the break.

What did you find out when you looked at the combo?

What is the most possible reason?

6. MAKE YOUR FOOD

Look at the list of possible causes and determine which of them are most probable and which are easier to believe.

Take decisions, which of the possible reasons are most probable, and check them first.

7. POSSIBLE YOUR STAY

Before starting the repair, check your pins and make sure they are correct.

Some possible reasons for the breakage can be checked without further testing. Check these reasons.

A further check will check the list of possible reasons for the break, and the actual cause will soon be found.

After an accurate determination of the reason for the breakdown, the dismantling and repair of the unit is not a trivial matter.

Access to diagnostic codes and error addresses

Display of information on diagnostics on the display

An information sheet is available for each address. Description contains details

provision of information.

They are listed by operation, therefore, all addresses related to one type of information,

are given together. In a number of systems, one and the same bits of information can be found in two or more addresses.

The diagram contains symbols that describe the image on the information display:

• n - numeric value

• 1 - displayed as 1 or 0. This means ON or OFF, which according to the description of the address

• x - information in the position of this sign has no meaning.

• _ - Probl. Display on display is absent

Diagnostic error codes

Each diagnostic trouble code (DTC) has a specific priority. DTC priority depends on how the DTC is displayed for the driver:

• Priority 1 - Angle display 1 stops normal operation, and DTC appears on the screen. This indicates a malfunction, at the appearance of which it is necessary to stop the vehicle, immediately turn off the engine and eliminate the malfunction. Corner set display 1 shows DTC until the error has been cleared.

• Priority 2 - The indicator of diagnostics on the display of 1 corner stand turns on. It indicates a problem that needs to be checked immediately

• Priority 3 - DTCs are written to memory, but the combiner is not shown.

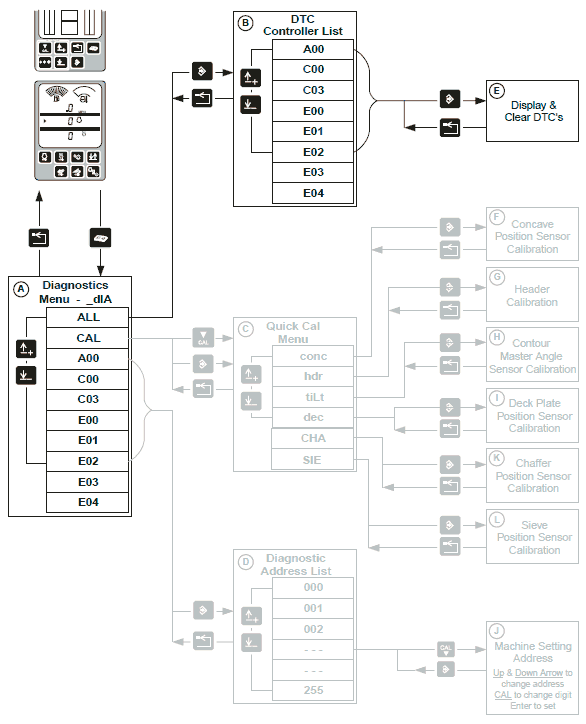

- A — Diagnostics menu

- B — Diagnostic codes

- C — Quick Calibration Menu

- D — List of addresses

- E — Display and delete diagnostic trouble codes

- F — Calibration of the recharge position sensor

- G — Header Calibration

- H — Calibration of the CONTOUR MASTER tilt sensor

- I — Deck position sensor

- J — Assigning Combine Addresses

- K — Calibration of the position sensor

- L — Calibration of the position sensor

Press the diagnostics button. On the display of the 1st corner stand dIA will appear.

Press the buttons up or down until you reach the desired address. For example, E01 appears on the display of 1 corner stand.

Press the input button.

Press the buttons up or down until you reach the desired address. For example, 125 appears on the display of 1 corner rack.

Press the input button.

Information on this address can be seen on the display of 1 corner post.

If the address is of DISPLAY / MODIFY type, the content should be changed.

• The first available charge will flash (on the middle or bottom line, depending on the type

reapers)

• Press the arrow keys down and up on the display to increase or decrease the value of the blinking mark.

• When the flashing value is correct, press the calibration button to go to the next discharge

• Continue changing the value successively with one sign until the CPD1 display does not

will show the required value.

• Press the input button to write the new value into the memory

Return to normal operating mode:

• Press the return arrow twice to return to normal operation

• Turn ignition switch OFF / OFF

• At the next start of the car in the combo, this calibration information will be used

GREENSTAR Warning Messages and Error Codes

HARVEST DOC and HARVEST MONITOR presets:

Messages from the controller (s) are transmitted to the GREENSTAR display via the CAN bus.

The warning is shown on the GREENSTAR display as a full page message. Cancel

A warning message by pressing the button next to the word CANCEL will lead to its closing.

The CAUTION notices shown in section “G” of the GREENSTAR display will be

display it after canceling the warning message WARNING. If problem

installed or no more, the CAUTION warning in section “G” is larger

will not be displayed. Internal error codes HARVEST DOC and HARVEST MONITOR:

The error codes can be seen by pressing the INFO button on the GREENSTAR display. Then press the button

next to the GreenStar display, then click on the button next to the words Recent Problems. This page will display the codes with a short description that follows. To read the error code (s), click on the button next to the words Fault Codes.

Diagnostic Trouble Codes

Group A00-A00 - Diagnostic codes of malfunctions of the engine control unit

A00 00091.09 - CAN bus communication on opening the throttle door is not correct or not already given priority 3

A00 000094.03 - Voltage in the fuel pressure sensor (cc # 722) above the permissible limits - more than 4.75 V constant current - priority 1

A00 000094.04 - Voltage from the sensor (cc # 135) of the fuel pressure below the permissible limits - priority 1

A00 000094.10 - Replenishment of pressure in the magistral - priority 2

A00 000094.13 - The readings of the fuel pressure sensor are higher than expected.

A00 000094.17 - At the start, the pressure in the motor does not develop after an uninterrupted cranking of the crankshaft - priority 2

A00 000097.03 - Voltage of the signal of the water sensor in fuel (cc # 136) above the permissible limits - priority 2

A00 000097.04 - Voltage in the water sensor in fuel (cc # 136) below the permissible limits - priority 2

A00 000097.31 - Water supplied with fuel - priority 2

A00 000100.01 - The oil pressure sensor is disconnected after the set of revolutions above the crank speed - priority 1

A00 000100.04 - Oil pressure sensor closed after engine stop - priority 2

A00 000 105.00 - Engine air temperature above 100 ° C (212 ° F) - priority 1

A00 000105.03 - Voltage in the air temperature sensor in the engine manifold above the permissible limits - priority 2

A00 000105.04 - Voltage in the air temperature sensor in the engine manifold below the permissible limits - priority 2

A00 000105.16 - Engine air temperature above 88 ° C (190 ° F) (moderate heavy duty) - priority 2

A00 000107.00 - Air filter filling switch signals about air filter filling - priority 2

A00 000110.00 - Engine coolant temperature above 115 ° C (240 ° F) (the most difficult duty) - priority 1

A00 000110.00 - Engine coolant temperature above 120 ° C (248 ° F) (heaviest duty) - priority 1

A00 000110.03 - Voltage of the engine coolant temperature sensor above the permissible limits - priority 2

A00 000110.04 - Voltage of the engine coolant temperature sensor below permissible limits - priority 2

A00 000110.15 - Engine coolant temperature above 105 ° C (221 ° F) - priority 2

A00 000110.16 - Engine coolant temperature above 110 ° C (230 ° F) - priority 2

A00 000111.01 - The level of the cooling liquid is lower than the standard. Engine coolant temperature above 125 ° C (257 ° F) - priority 1

A00 000158.17 - The controller is not running properly - priority 2

A00 000174.03 - Voltage in the fuel temperature sensor in the engine above the permissible limits - priority 2

A00 000174.04 - Voltage in the fuel temperature sensor in the engine below the permissible limits - priority 2

A00 000174.16 - Fuel temperature in the engine above the normal range (over 65 ° C / 149 ° F) - priority 2

A00 000174.16 - Fuel temperature in the engine above the normal range (over 80 ° C / 176 ° F) - priority 2

A00 000611.03 - The driver of the cell has a short circuit to the battery in the guide to the cell - priority 1

A00 000611.04 - The driver has provided a short circuit to the mass in the guide to the fork - priority 1

A00 000620.03 - Internal (5-volt) constant voltage of the engine control unit out of range or too high - priority 2

A00 000620.04 - Internal (5-volt) constant voltage of the engine control unit out of range or too low - priority 2

A00 000627.01 - All current values on the display outside the standard - priority 2

A00 000636.02 - Electrical disturbances detected at the pump position sensor + (cc # 172) and / or the pump position sensor - (cc # 173) - priority 2

A00 000636.08 - No signal from the pump position sensor - priority 2

A00 000636.10 - Incorrect timing diagram of pulse tracking on the pump position sensor - priority 2

A00 000637.02 - At engine speed sensor + (cc # 174) and / or (cc # 175) electric noise is equipped - priority 2

A00 000637.07 - Incorrect position of the engine speed sensor and the pump position sensor - priority 2

A00 000637.08 - Missing signal from engine speed sensor - priority2

A00 000637.10 - Incorrect timing diagram of pulse tracking on the engine speed sensor - priority 2

A00 651.05 - Topcynk # 1 lower expected - priority 2

A00 000651.06 - Topcynk # 1 is too fast - priority 2

A00 000651.07 - Fuel supply to cylinder # 1 lower than expected - priority 2

A00 000652.05 - Topcynk # 2 below expected - priority 2

A00 000652.06 - Token # 2 is too fast - priority 2

A00 000652.07 - Fuel supply to cylinder # 2 lower than expected - priority 2

A00 000653.05 - Topcynk # 3 below expected - priority 2

A00 000653.06 - Topcynk # 3 is too fast - priority 2

A00 000653.07 - Fuel supply to cylinder # 3 lower than expected - priority 2

A00 000654.05 - Topcynk # 4 lower expected - priority 2

A00 000654.06 - Topcynk # 4 is too fast - priority 2

A00 000654.07 - Fuel supply to cylinder # 4 lower than expected - priority 2

A00 000655.05 - Topcynk # 5 below expected - priority 2

A00 000655.06 - Topcynk # 5 is too fast - priority 2

A00 000655.07 - Fuel supply to cylinder # 5 is lower than expected - priority 2

A00 000656.05 - Topcynk # 6 below expected - priority 2

A00 000656.06 - Topcynk # 6 is too fast - priority 2

A00 000656.07 - Fuel supply to cylinder # 6 lower than expected - priority 2

A00 000676.03 - Output signal (cc # 191) from the ignition spark plug heater is high, if the engine control unit does not supply power to the boiler 2

A00 000676.05 - The output signal (cc # 191) from the ignition spark plug heater is low, if the engine control unit supplies power to the boiler

A00 000931.11 - Gear pump signal (cc # 36) indicates the presence of a disconnect or short circuit - priority 2

A00 001080.03 - Overvoltage supply of the pressure sensor in the magistral (cc # 721) - priority 1

A00 001080.04 - Undervoltage supply of the pressure sensor in the magistral (cc # 721) - priority 1

A00 001347.03 - The driver has detected an undershoot in the circuit of the solenoid pump (cc # 178) - priority 1

A00 001347.05 - The driver has detected an undershoot in the pump solenoid circuit (cc # 176) - priority 1

A00 001347.05 - The driver has detected an undershoot in the pump solenoid circuit (cc # 176) - priority 2

A00 001347.07 - The pressure control system in the magistral cannot get the correct pressure in the magistral - priority 2

A00 001347.10 - Solenoid 1 pump does not provide the expected fuel supply - priority 2

A00 001348.05 - The driver has detected an undershoot in the circuit of the solenoid pump 2 (cc # 179) - priority 2

A00 001348.10 - Pump solenoid 2 does not provide the expected fuel supply - priority 2

A00 001569.31 - Engine protection - power reset due to other faults - priority 2

A00 002000.13 - Weakening the protection of the engine control unit - priority 1

Group C00-C00 - Diagnostic codes of malfunctions of the control unit in the armrest

C00 000158.04 - Control circuit power supply (cc # 023) below 10.5 V DC - priority 3

C00 000 170.03 - Overvoltage at the CLIMATRAK sensor, air temperature in the cab - more than 4.8 V DC - priority 3

C00 000 170.04 - Undervoltage at the CLIMATRAK sensor, air temperature in the cab - less 0.1 V of the constant current - priority 3

C00 000172.03 - Overvoltage on the CLIMATRAK sensor of the external air temperature - more than 4.8 V constant current priority 3

C00 000172.04 - Undervoltage at the CLIMATRAK sensor of the external air temperature - less 0.1 V constant current - priority 3

C00 000190.09 - Lack of CAN communication from engine control - Engine speed - priority 3

C00 000605.04 - Ha CLIMATRAK low pressure switch (cc # 914) 12 V DC - priority 3

C00 000627.03 - Delay voltage (cc # 006) above 16 V DC - priority 1

C00 000627.04 - Delay voltage (cc # 006) below 10.5 V DC - priority 3

C00 000628.12 - The controller cannot exit the block program of the initial download - priority 1

C00 000630.11 - The controller did not hold the EEPROM test on power-up - priority 1 C00 000639.19 - CAN bus messages were not correctly assigned or priority 3 was accepted

C00 000875.04 - CAN bus communication with left-hand control - CLIMATRAK clutch signal (cc # 913) 12 V DC - priority 3

C00 001490.08 - Feeder chamber speed unknown - priority 2

C00 001498.11 - Signal from the header switch on switch indicates opening, short circuit, high voltage or high temperature - priority 3

C00 001499.11 - The signal from the switch on of the heater indicates opening, short circuit, high voltage or high temperature - priority 3

C00 001499.12 - Schedule of malfunctions of turning on the unit, priority 2 has been detected

C00 001504.11 - Seat switch was closed within 6 hours in a row - priority 1

C00 001547.03 - CLIMATRAK Overvoltage on the temperature sensor inside the controller - more than 4.47 V constant current priority 3

C00 001547.04 - CLIMATRAK Undervoltage at the temperature sensor inside the con- ditioner - below 0.1 V constant current priority 3

C00 001548.03 - CLIMATRAK Overvoltage on the outlet air temperature sensor - more than 4.8 V constant current priority 3

C00 001548.04 - CLIMATRAK Undervoltage at the outlet air temperature sensor - below 0.1 V constant current priority 3

C00 001549.07 - CLIMATRAK Positioning the water valve more than 30% different from the given priority 3

C00 200017.09 - No CAN bus communication (s) from corner post control unit - priority 3

C00 200018.09 - No CAN bus communication (s) from the left control unit - priority 3

C00 200 201.11 - Incorrect signals from the power switch - priority 3

C00 200202.11 - Incorrect signals from the power switch - priority 3

Group C03 — C03 - Diagnostic codes of malfunctions of the corner stack control unit

C03 000096.09 - Lack of CAN communication from the right control unit - fuel level - priority 3

C03 000110.09 - Lack of CAN communication from engine control unit - engine coolant temperature - priority 3

C03 000190.09 - Lack of CAN communication from engine control - Engine speed - priority 3

C03 000627.03 - Delay voltage (cc # 006) above the permissible limits - above 16 B constant current - priority 3

C03 000628.12 - The controller cannot exit the block program of the initial download - priority 1

C03 000630.11 - EEPROM did not pass test on power-up - priority 1

C03 000639.19 - CAN bus messages were not assigned correctly or priority 3 was accepted

C03 001079.03 - Overvoltage on the recharge position sensor - more than 5.5 V constant current - priority 3

C03 001079.04 - Undervoltage on the trim position sensor - less than 4.5 V DC.

C03 001486.03 - Voltage of the recharge position sensor too high - more than 4.5 V DC - priority 3

C03 001486.04 - Voltage of the recharge position sensor too low - less than 0.5 V DC current - priority 3

C03 001487.03 - Overvoltage of the blinking light - more than 4.5 V DC - priority 3

C03 001487.04 - Undervoltage of the blinking light - less than 0.5 V DC - priority 3

C03 001492.08 - Signal from the driver of the interior light in the cab has opened a circuit breaker, short circuit, high voltage or high temperature

C03 001493.09 - Lack of CAN communication from main waste sensor - waste volume - priority 3

C03 001500.11 - The switch on block 1 of the corner post display does not work for more than 30 seconds - priority 3

C03 001501.11 - The switch on the block 2 of the corner post display does not work for more than 30 seconds, priority 3

C03 001502.11 - The switch on the block 3 of the corner post display does not work for more than 30 seconds - priority 3

C03 001503.09 - Lack of CAN bus communication from control unit in armrest - Status of armrest switch - priority 3

C03 001510.09 - Lack of CAN communication from the right control unit - Temperature on the combo - priority 3

C03 001511.09 - Lack of CAN communication from the right control unit - Loss of grain - priority 3

C03 001486.03 - Voltage of the recharge position sensor too high - more than 4.5 V DC - priority 3

C03 001486.04 - Voltage of the recharge position sensor too low - less than 0.5 V DC current - priority 3

C03 001487.03 - Overvoltage of the blinking light - more than 4.5 V DC - priority 3

C03 001487.04 - Undervoltage of the blinking light - less than 0.5 V DC - priority 3

C03 001492.08 - Signal from the driver of the interior light in the cab has opened a circuit breaker, short circuit, high voltage or high temperature

C03 001493.09 - Lack of CAN communication from main waste sensor - waste volume - priority 3

C03 001500.11 - The switch on block 1 of the corner post display does not work for more than 30 seconds - priority 3

C03 001501.11 - The switch on the block 2 of the corner post display does not work for more than 30 seconds, priority 3

C03 001502.11 - The switch on the block 3 of the corner post display does not work for more than 30 seconds - priority 3

C03 001503.09 - Lack of CAN bus communication from control unit in armrest - Status of armrest switch - priority 3

C03 001510.09 - Lack of CAN communication from the right control unit - Temperature on the combo - priority 3

C03 001511.09 - Lack of CAN communication from the right control unit - Loss of grain - priority 3

C03 001515.09 - Lack of CAN communication from header control unit - Header settings - priority 3

C03 001552.03 - CLIMATRAK Overvoltage for setting the temperature - more than 4.5 V DC - priority 3

C03 001552.04 - CLIMATRAK Reduced voltage for setting the temperature - below 0.5 V DC - priority 3

C03 001552.13 - CLIMATRAK Temperature setting not calibrated - priority 3

C03 001553.03 - CLIMATRAK Overvoltage of the clean fan speed control system - more than 4.5 V constant current priority 3

C03 001553.04 - CLIMATRAK Undervoltage of the fan speed control system - lower 0.5 V constant current priority 3

C03 001553.13 - CLIMATRAK Cleaning fan speed setting not calibrated - priority 3

C03 001565.09 - Lack of CAN communication from the control unit in the armrest - Status of starting the engine and the header - priority 3

C03 001567.09 - Lack of CAN bus communication from header control unit - Control mode - priority 3

C03 100 100.09 - Lack of CAN bus communication from the left control unit - System data - priority 3

C03 100101.09 - Lack of CAN bus communication from the left control unit - System data - priority 3

C03 100106.11 - Switch on block 4 of the corner post display does not work for more than 30 seconds - priority 3

Group E00-E00 - Diagnostic codes of malfunctions of the main waste sensor

E00 000190.09 - Lack of CAN communication from engine control unit - Engine speed - priority 3

E00-E00 000628.12 - The controller cannot exit the block program of the initial download - priority 2

E00-E00 000630.11 - EEPROM failed test on power up 2

E00-E00 000639.09 - The main waste management unit does not receive the modern CAN bus - priority 3

E00-E00 000639.19 - CAN bus messages were not assigned correctly or priority 3 was accepted

E00-E00 001493.11 - Fault in the waste system - priority 3

E00-E00 001493.15 - Calibration of the waste system oversized - priority 3

E00-E00 001493.17 - Calibration of the waste system is undershot - priority 3

E00-E00 001494.08 - Recognized photo element in the main waste sensor - priority 3

E00-E00 001 494.11 - Main waste sensor malfunction - priority 3

E00-E00 001 495.08 - Rediscovery of photo elements in the secondary waste sensor priority 3

E00-E00 001495.11 - Main waste sensor malfunction - priority 3

E00-E00 001 496.07 - Missing waste electric motor - priority 3

E00-E00 001511.09 - Lack of CAN communication from the right control unit - Grain size - priority 3

E00-E00 001565.09 - Lack of CAN communication from the control unit in the armrest - the processor and the header are on - priority 3

E00-Group E01-E01 - Diagnostic codes of malfunctions of the header control unit

E01 000084.09 - Lack of CAN bus communication from corner stack control unit - Wheel speed - priority 3

E01 000190.09 - Lack of CAN communication from engine control unit - Engine speed - priority 3

E01 000627.03 - Overvoltage on the controller - more than 16 V DC - priority 1

E01 000628.12 - The controller cannot exit the block program of the initial download - priority 1

E01 000630.11 - The system is not calibrated or the EEPROM did not stand the power-on test - priority 3

E01 000639.13 - The header control unit does not receive the current communication of the CAN multi-bus system - priority 3

E01 000639.19 - CAN bus messages were not correctly assigned or accepted - priority 2

E01 001079.03 - Overvoltage at the height sensor (cc # 481) - more than 5.25 V DC - priority 2

E01 001079.04 - Undervoltage at the height sensor (cc # 481) - less than 4.75 V DC - priority 2

E01 001080.03 - Overvoltage at height sensor 2 (cc # 471) - more than 5.25 V constant current priority 2

E01 001080.04 - Undervoltage at height sensor 2 (cc # 471) - less than 4.75 V constant current priority 2

E01 001515.13 - Active elevation control or CONTOUR MASTER not calibrated for a specific external header - priority 2

E01 001516.13 - The system of the "floating" mode of the header is not calibrated for a specific external header - priority 2

E01 001518.02 - The voltage in the circuit (codes 436, 487, 488 and 489) has been changed during the operation of the active control system in the automatic mode - priority 3